The importance of rubber ring static sealing tension in sealing technology

Abstract: The tensile value of rubber ring static seal is of great significance in sealing technology. In the design and production process, factors such as rubber ring material, cross-section shape and application environment should be fully considered to ensure the reliability, safety and service life of the sealing system.

With the rapid development of modern industrial technology, sealing technology is playing an increasingly important role in various engineering fields. As one of the main components of static sealing, the rubber ring plays an important role in the sealing system. The static sealing tension of the rubber ring is very important to ensure the reliability and safety of the sealing system. In this paper, the tensile quantity of rubber ring static seal is discussed, its importance and influencing factors are analyzed, and the corresponding design and production requirements are put forward.

First, the importance of rubber ring static seal tensile amount

1. Ensure sealing performance

The static sealing tension of rubber ring directly affects the sealing performance of the sealing system. When the rubber ring is working under a certain amount of tension, the contact pressure between it and the sealed surface is evenly distributed, which can ensure that the sealing system has good sealing performance. If the tensile amount is too large or too small, it will lead to uneven distribution of contact pressure, thereby reducing the sealing performance.

2. Improve the service life of the sealing system

The reasonable design of rubber ring static seal tension can improve the service life of the sealing system. The appropriate amount of tension can reduce the friction between the rubber ring and the sealed surface, reduce wear, and extend the service life of the sealing system.

3. Ensure the safety of the sealing system

The reasonable design of the static sealing tension of rubber ring is very important to ensure the safety of the sealing system. When the rubber ring is working under a certain amount of tension, it has good resilience and can effectively prevent the leakage of the sealing system. At the same time, the appropriate tensile amount can also improve the tensile strength of the rubber ring to prevent the sealing system from breaking and other safety problems during operation.

Second, the factors that affect the tensile amount of rubber ring static seal

Second, the factors that affect the tensile amount of rubber ring static seal

The choice of rubber ring material has an important effect on the static sealing tensile gauge. Different rubber materials have different elasticity, strength and wear resistance, so it is necessary to choose the appropriate rubber material according to the actual application scenario when designing the rubber ring.

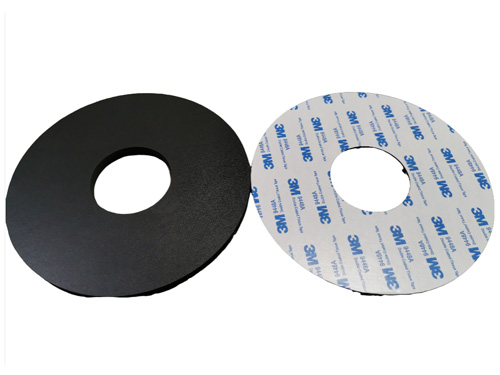

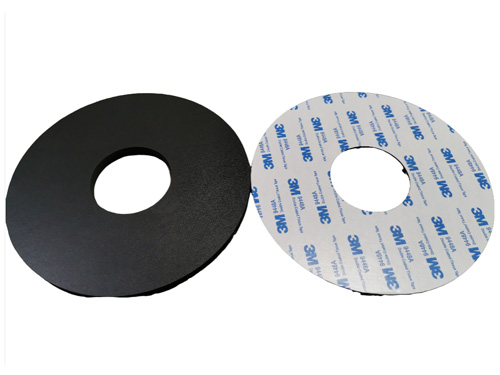

2. Section shape of rubber ring

The cross-section shape of the rubber ring also has a great influence on the tensile amount of the static seal. Different section shapes have different elastic and tensile strength, so the design should be based on the actual application needs to choose the appropriate section shape.

3. State of the sealed surface

Factors such as the flatness and finish of the sealed surface also affect the tensile amount of the rubber ring static seal. Uneven surface, sand and other impurities will affect the contact pressure distribution between the rubber ring and the sealed surface, thus affecting the static seal tensile amount.

Factors such as the flatness and finish of the sealed surface also affect the tensile amount of the rubber ring static seal. Uneven surface, sand and other impurities will affect the contact pressure distribution between the rubber ring and the sealed surface, thus affecting the static seal tensile amount.

Factors such as the flatness and finish of the sealed surface also affect the tensile amount of the rubber ring static seal. Uneven surface, sand and other impurities will affect the contact pressure distribution between the rubber ring and the sealed surface, thus affecting the static seal tensile amount.

Factors such as the flatness and finish of the sealed surface also affect the tensile amount of the rubber ring static seal. Uneven surface, sand and other impurities will affect the contact pressure distribution between the rubber ring and the sealed surface, thus affecting the static seal tensile amount.

1. Choose the right rubber material

In the rubber ring design process, the appropriate rubber material should be selected according to the actual application scenario. For example, in high temperature environments, rubber materials with excellent high temperature resistance can be selected; In the case of chemical media, rubber materials with good chemical resistance should be selected.

2. Design a reasonable cross-section shape

The design of the section shape of the rubber ring should fully consider the static sealing tensile amount, elasticity, tensile strength and other factors. Different cross-section shapes such as round, square, O-type can be selected according to the actual application needs.

3. Ensure the quality of rubber ring production

In the production process of rubber rings, the production process should be strictly controlled to ensure the quality of rubber rings. For example, during the vulcanization process, parameters such as vulcanization temperature and time should be controlled to ensure that the rubber ring has good elastic and tensile strength.

In short, the tensile value of rubber ring static seal is of great significance in sealing technology. In the design and production process, factors such as rubber ring material, cross-section shape and application environment should be fully considered to ensure the reliability, safety and service life of the sealing system.

13423005859

13423005859

中文

中文 EN

EN